| Case Study 1 – Retrofit Fresh Food Sealing Machine for new Pottle Shape Fresh food supplier who was packaging food using specialised Italian pottle sealing machinery. They wanted to change their pottle shape to a different size to meet a new market opportunity. |

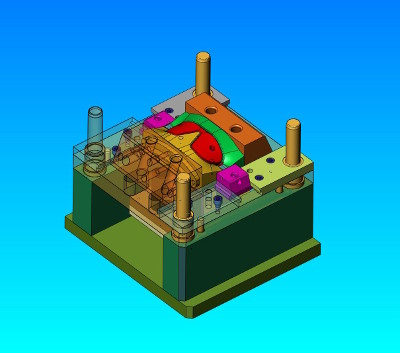

| Case Study 2 – Coloured Plant Pot Tooling Importer and distributor of seeds who wanted to broaden his product offerings. We designed, prototyped and built plastic injection moulding tools for the new pot plant and the saucer. |

| Case Study 3 – Ducting Cap Tooling Project Client who wanted to save money on his imported plastic “Duct Caps”. We modelled up a replacement product and did analysis of the tooling and moulding costs for the project. |

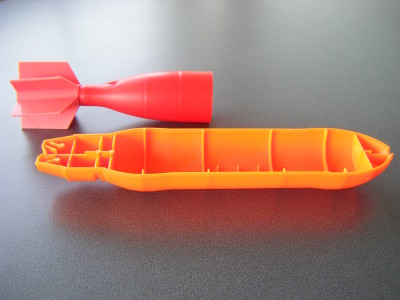

| Case Study 4 – Avalanche Bomb Development Avalanche bombs are critical in the area of ski-field management. Absolute Tooling was involved in the product design, prototypes, trialling and finally tooling to create the orange “bomb” that you see. |

| Case Study 5 – The “Safe Eyes” Story Tooling was designed to over-mould the gauze visor with newly designed plastic goggles. |

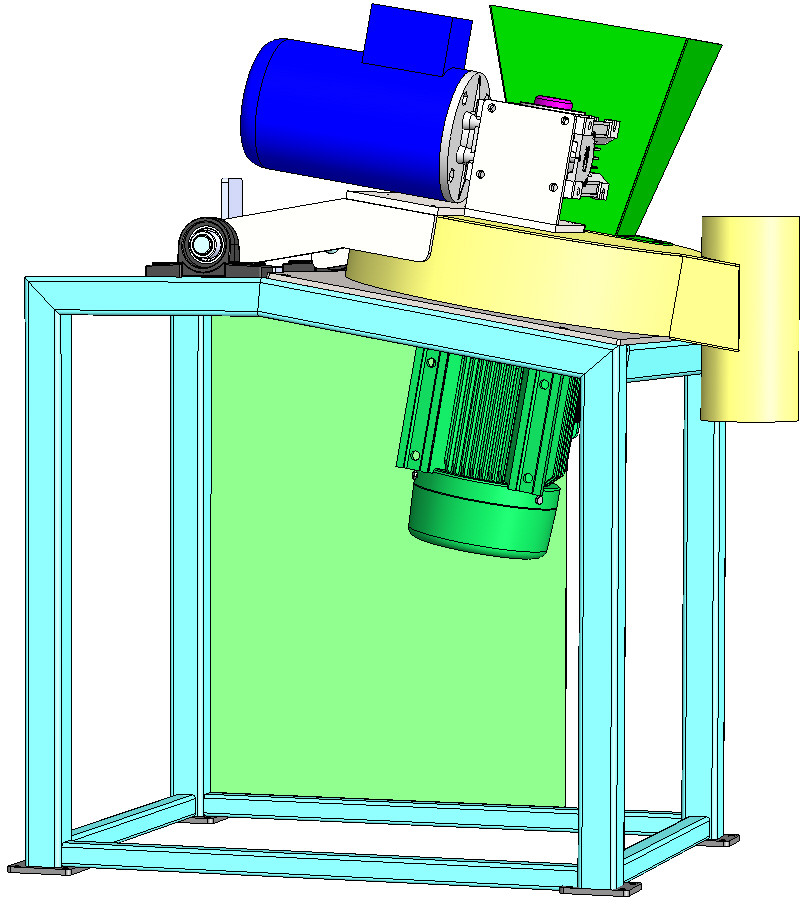

| Case Study 6 – Cookie Spoon Machine We designed, built and tested a machine that manufactures full 3D spoon-shaped biscotti biscuits for a niche NZ based client. |

| Case Study 7 – Muesli Bar Roller We designed and built a one-off specialist muesli bar roller for an international dairy company. |

| Case Study 8 – Chestnut Sheller Absolute Tooling designed and built this Chestnut Sheller under license to the NZ Chestnut Council. |